The Role of Material Testing in Ensuring Quality Omega 3 Fish Oil Supplements

Material testing plays a crucial role in maintaining the quality and efficacy of omega 3 fish oil supplements. In this article, we explore how various testing methods, including hardness, rupture, and compression testing, contribute to ensuring the integrity, stability, and safety of these essential health products.

Understanding Material Testing for Omega 3 Fish Oil Supplements

Material testing encompasses a range of techniques aimed at evaluating the physical, chemical, and mechanical properties of raw materials, intermediate products, and finished supplements. For omega 3 fish oil supplements, material testing is essential to verify the quality of ingredients, assess product stability, and confirm compliance with regulatory standards.

Key Testing Methods for Omega 3 Fish Oil Supplements

Purity Testing: Purity testing involves analyzing the concentration of omega 3 fatty acids (EPA and DHA) in fish oil extracts. High-performance liquid chromatography (HPLC) and gas chromatography (GC) are commonly used methods to quantify the levels of EPA and DHA, ensuring that supplements meet label claims and regulatory requirements.

Oxidation Testing: Oxidative rancidity is a common concern in fish oil supplements due to their susceptibility to oxidation. Testing methods such as peroxide value (PV), anisidine value (AV), and total oxidation (TOTOX) value assess the extent of lipid oxidation, indicating product freshness and stability.

Heavy Metal Testing: Heavy metal contamination, particularly mercury, lead, and cadmium, is a significant risk associated with fish oil supplements. Inductively coupled plasma mass spectrometry (ICP-MS) and atomic absorption spectroscopy (AAS) are employed to detect and quantify heavy metal levels, ensuring product safety and compliance with regulatory limits.

Microbiological Testing: Microbiological testing is conducted to evaluate the microbial purity of fish oil supplements and detect the presence of harmful pathogens such as bacteria, yeast, and mold. Standard methods include total plate count, yeast, and mold count, and tests for specific pathogens such as Salmonella and E. coli.

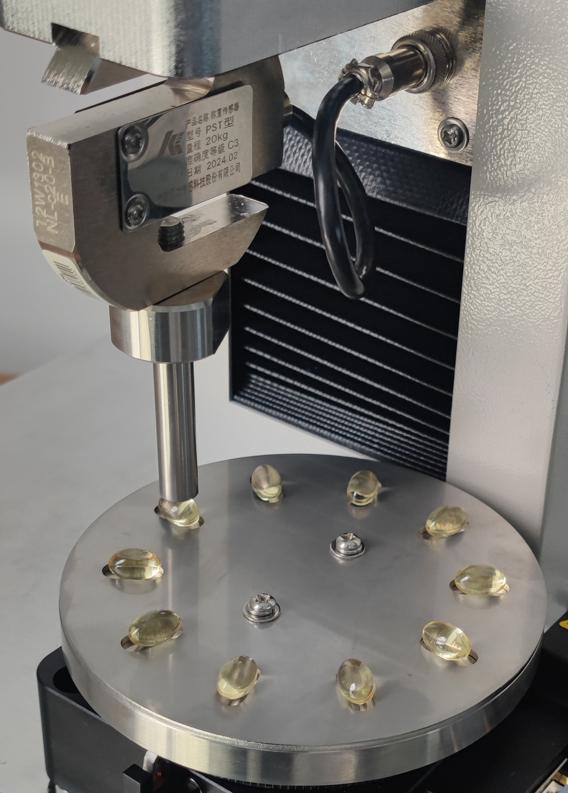

Compression Testing: Compression testing assesses the hardness and resistance to rupture of softgel capsules containing fish oil. This method involves applying controlled pressure to the capsules and measuring the force required for deformation or breakage. It ensures the integrity of the capsules and prevents leakage or loss of potency.

Adhering to Regulatory Standards

Manufacturers of omega 3 fish oil supplements must adhere to various regulatory standards, including those set by the Food and Drug Administration (FDA), United States Pharmacopeia (USP), and other international organizations. Compliance with Good Manufacturing Practices (GMP) ensures that supplements are manufactured under stringent quality control measures, including rigorous material testing protocols.

Conclusion

In conclusion, material testing, including hardness, rupture, and compression testing, plays a critical role in ensuring the quality, safety, and efficacy of omega 3 fish oil supplements. By employing comprehensive testing methods, manufacturers can verify the purity, stability, and compliance of their products, providing consumers with reliable and beneficial supplements for maintaining optimal health and well-being.

Reach Cell Instruments for more testing methods. We are waiting for your call.

Comments

Post a Comment